What is the Split Tensile Strength of Concrete and Why We Measure it?

The split tensile strength of concrete is one of the basic and important properties which greatly affect the extent and size of cracking in structures. The concrete is not usually expected to resist the direct tension due to its low tensile strength and brittle nature.

However the determination of split tensile

strength of concrete is necessary to determine the load at which the concrete

members may crack. The test split tensile strength of concrete is very simple to perform and the most important

fact is that it gives uniform results than the other tension tests like ring

tension test and double punch test.

DETERMINATION

OF SPLIT TENSILE STRENGTH OF CONCRETE AS PER IS: 5816: 1999 AND IS: 456: 2000

Hi friends, you are welcomed in the world

of Civil

Allied Gyan. Read definition, apparatus, IS code, detailed

procedure, observations, formula, result, lab report about split tensile

strength of concrete.

Apparatus Required for Split Tensile Strength of Concrete

Test:-

- Compression testing machine

- Tamping rod

- Weighing device

- Tools and containers for mixing

- Tamper

- IS: 456: 2000, Code for method of practice for plain and reinforced concrete

- IS: 5816: 1999, Method of test for split tensile strength of concrete

Advantage

of Test for Split Tensile Strength of Concrete:-

- Same type and same specimens can also be used for compression test.

- The test split tensile strength of concrete is simple to perform and the most important fact

is that it gives uniform results than the other tension tests like ring tension

test and double punch test.

Preparation

of Concrete Cube Specimens

Sampling of Materials – Samples

of aggregates and cement for each batch of concrete will be of the desired

grading and will be in an air-dried condition. On

arrival at the laboratory, the cement samples will be thoroughly mixed dry

either by hand or in a suitable mixer in such a manner as to ensure the

greatest possible blending and uniformity in the material.

Proportioning

– The proportions of the materials (aggregates, cement,

water, etc.) will be similar in all respects to those to be employed in the

work.

Weighing – The quantities of cement, each size of aggregate and

the amount of water for each batch will be determined by weight to an accuracy

of 0.1 % of the total weight of the batch.

Mixing Concrete – The cement and aggregates

are mixed by hand or preferably in a laboratory batch mixer in such a manner as

to avoid loss of water or other materials. It is done until the mixture ensures

the greatest possible blending and of uniform color.

*Each batch of concrete will be of such a size as to leave

about 10 percent excess after moulding the desired number of test specimens.

Mould – The cylindrical mould will be of 150 mm diameter and

300 mm height conforming to IS: 10086-1982.

Compacting – The test specimens will be made as soon as practicable after

mixing.

- The moulds will be wiped clean and applied oil here.

- The obtained concrete will be filed in the moulds in layers approximately 5 cm thick.

- Each layer will be compacted with not less than 35 strokes per layer using a tamping rod (a steel bar of 16 mm diameter and 60 cm long, bullet pointed at lower end).

- The top surface will be leveled and smoothed with a trowel.

Curing – The test specimens will be stored in a place free from

vibration in moist air of at least 90 percent relative humidity and at a

temperature of 25 °C to 29 °C for 24 hours ± ½ hour

from the time of addition of water to the dry ingredients. After this period

the specimens will be marked and removed from the moulds and kept submerged in

clear freshwater until taken out prior to the test.

Procedure for

Determination of Splitting Tensile Strength of Concrete:-

- The specimens will be removed from the water after specified curing time and wiped out excess water from the surface. The dimensions of the specimens will be noted to the nearest 0.2m.

- The bearing surfaces of the compression testing machine will be wiped clean. And any loose sand or other materials will be removed from the surfaces of the specimens which are to be in contact with the rollers.

- Two bearings strips of nominal (1/8 inch i.e. 3.175 mm) thick plywood free of imperfections approximately (25 mm) wide and of length equal to or slightly longer than that of the specimen should be provided for each specimen.

- These two bearing strips (plywood strips) are placed between the specimen and both the upper and lower bearing blocks of the strength testing machine. Also they can be placed between the specimen and the supplemental bars or plates.

- Now draw diametric lines at each end of the specimen using a suitable device that will make sure that they are in the same axial plane.

- One of the bearing strips (plywood strips) will be centered along the centre of the lower bearing block.

- The specimen will be

placed on the bearing strip (plywood strip) and aligned carefully so that the lines marked on the ends of the specimen will be

vertical and cantered over the plywood strip.

- The second plywood strip (bearing strip) will be placed lengthwise on the cylinder, cantered on the lines marked on the ends of the cylinder.

- The load will be applied continuously and without shock, at a constant rate within, the range of 689 to 1380 kPa/min splitting tensile stress until failure of the specimen.

The maximum applied load

indicated by the testing machine at failure will be recorded. Also the type of

failure and appearance of fracture will be noted.

Observation and Calculation:-

1) Mix proportion =………………………………..

2) Date of casting=………………………………….

3) Date of Testing=………………………………….

4) Age of concrete=………………………………….

Table: Splitting tensile strength of concrete

Trail No 1

|

Trail No 2

|

|

Wt. of specimen (kg)

|

||

Diameter of specimen (mm)

|

||

Length of

Specimen (mm)

|

||

Failure load P

(mm)

|

||

Split tensile strength

|

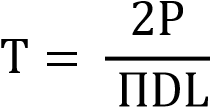

Formula for split tensile

strength of concrete:-

Calculate the splitting tensile strength of the concrete specimens

as follows:-

Where D is the Diameter (in meter), L is the length (in

meter), P is the maximum applied load indicated by testing machine (in kN), T

is the splitting tensile strength of concrete and ∏ = 22/7.

Result:-

The average split tensile strength of concrete sample in 7

days is found to be …..…..

The average split tensile strength of concrete sample in 28

days is found to be …..…..